We have material scientists, engineers and chemists on staff with extensive knowledge of material properties and how they relate to specific applications. We will ensure the ideal material, or combination of materials, is used for your specific application and environment – saving you time, money, and reputation.

Within our Testing Lab, we are able to identify the type of polymer being used and the various additives contained within, down to the parts-per-billion. Receiving your specific chemical “recipe” allows you to determine how your product will work in various environments or to reach an answer to a product failure. This analysis allows us to formulate a custom material specific to your product’s needs.

Liquid Silicone Rubber is used an a wide variety of applications due to its biocompatibility and durability, while also being temperature and chemical resistant. It is a material extremely useful in medical devices and infant care products but also found in many other specialized industries. Whether you are looking for a short-run production or some R&D for design or failure analysis, PSN has this unique capability in-house.

Developing custom materials for a variety of applications like selective sorbent systems, conductive compounds, highly or uniquely filled materials, or even for specific tribology requirements has historically been a part of PSN’s business model. We have several compounding lines with a variety of downstream processing equipment to meet many common polymer processing needs.

Once your custom material is created, our team can then provide material to your supplier base or potentially mold the final product right in our facility for you.

Our team has a diverse range of experience in processing for your prototyping and manufacturing needs including:

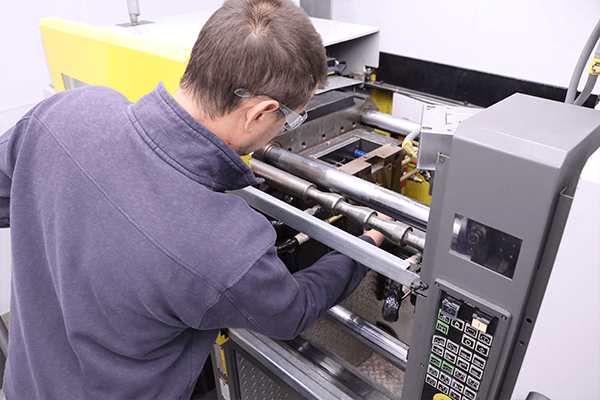

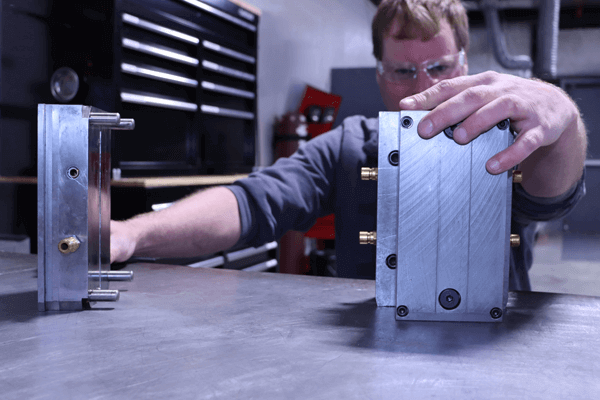

At PSN, our Processing Lab includes a Machining Center to build the tooling necessary to create a functional prototype, giving you a mock version of your product. We offer customizable Master Unit Dies (MUDs) to reduce expenses when possible or can also create a standalone tool to use to mold your product. This phase of development is important to work out potential issues or failures before reaching the manufacturing floor. This allows you to streamline your production processes, ultimately keeping design costs lower.

While we are not currently a full-blown manufacturing facility, we do run production lines in certain cases, typically for low-volume needs. We have the equipment and expertise to get your parts out in a timely manner and will offer production suggestions if it is not something we do in-house.

The team at PSN Labs is well versed in mold qualifications. Whether using an already established internal qualification method or assisting in the creation of mold qualifications, we are flexible and work with the individual needs of our clients. We utilize the following processes to ensure quality control needs are met:

We also provide unique processing services such as molding high temperature resins (PBI and PEEK), overmolding and two-shot molding.

PSN Labs has a variety of molds available to assist in specimen creation for ASTM, ISO, and VDI 2019 Testing, along with many generic shapes available to analyze the touch and feel of a material in finished form or view the aesthetic of a surface finish. Additionally, we have custom molds to analyze adhesion between two thermoplastic resins or LSR over a thermoplastic resin. We often combine these shapes for processing studies to allow for a deeper analysis of how the process is affecting the material properties.

With the advances made in polymer engineering over the last several decades, the ability to produce stronger, lighter, more durable, sustainable, and less expensive structural components is advancing greatly. We have extensive knowledge and background in metal to polymer conversions and routinely provide this service to our client base.